The COVID-19 has accelerated the digital transformation. Led by the megatrend of 5G and high-performance computing (HPC), the global semiconductor production capacity will fall short of demand in 2021, but it will also lead to the problem of chip shortage in the electronic production chain. In order to ensure the capacity of wafer foundry, IDM factory and IC design factory expanded their orders to strive for more chip production, including Liandian, Li Jidian, and the world's advanced companies, which have successively increased their prices in 2021, with an average increase of 20~30%. However, TSMC did not increase the price in 2021, and the wafer foundry price remained unchanged from 2020.

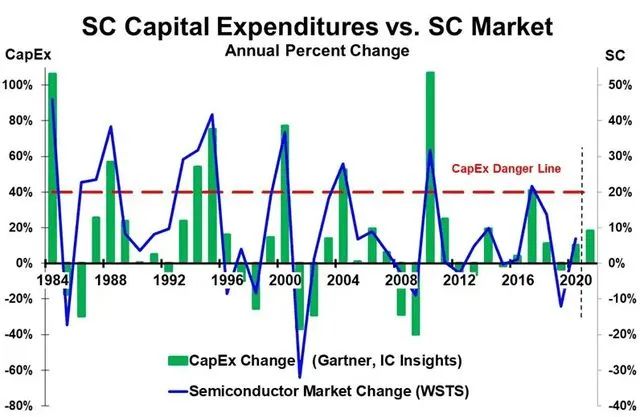

Although the global semiconductor factories have increased their capital expenditure to expand their capacity, the equipment delivery period has been significantly extended to more than 9 months, resulting in a limited expansion of capacity in 2021-2022. In the case that the shortage of chips is expected to continue to 2023-24, TSMC decided to increase the wafer OEM price when negotiating with customers for the 2022 new contract, the mature process price increased by 15~20%, and the advanced process price increased by about 10%, The new price will apply to the shipment of wafers in 2022.

According to the IC design industry, in the fourth quarter, due to the adjustment of the wafer foundry in terms of the short and long material conditions, the price was not adjusted by other manufacturers except for the price increase of Liandian. After the news that TSMC will raise the price of wafer foundry in 2022 came out, other wafer foundry factories that had been standing still have taken new actions recently, including Liandian, Li Jidian, and the world's advanced manufacturers, which will follow up the price increase in the first quarter, with an average increase of more than 10%, which also indicates that the price of wafer foundry will rise in 2022.

The wafer foundry pointed out that in the first half of 2022, the capacity has been fully booked by customers, and more than 90% of the capacity has been sold out in the second half of 2022. The order visibility has seen the second half of 2022. Since the industry is optimistic that the problem of chip shortage will continue beyond 2023 after the epidemic slows down and the economy is unblocked, more than half of customers choose to sign a 2-3 year long contract. The manufacturer explained that the overall price increase of the wafer foundry in the first quarter of 2022 was a foregone conclusion, and the price increase would be even higher if no long-term contract was signed.

Jibang Technology, a market survey agency, said that the demand for semiconductors led by 5G has gradually fermented since the second half of 2019. In addition to the increasingly tense geopolitical factors, it will extend to the COVID-19 in 2020, accelerating the demand for global digital transformation. The epidemic has driven panic stocking, which has brought structural changes to semiconductor supply and demand, resulting in a serious shortage of wafer foundry capacity. So far, the situation has not stopped.

It is estimated that in 2022, the average annual production capacity of the global wafer foundry will increase by about 6%, and that of the 12-inch wafer foundry will increase by about 14% annually. More than half of the new capacity of the 12-inch wafer foundry will be the most scarce mature manufacturing process. It is expected that the extremely tight wafer shortage tide at this stage will be relieved.

ch

ch English

English